Produced by the Spanish Association of Ceramic Tile Manufacturers, this didactic and enlightening documentary shows in detail the production process of ceramic tiles.

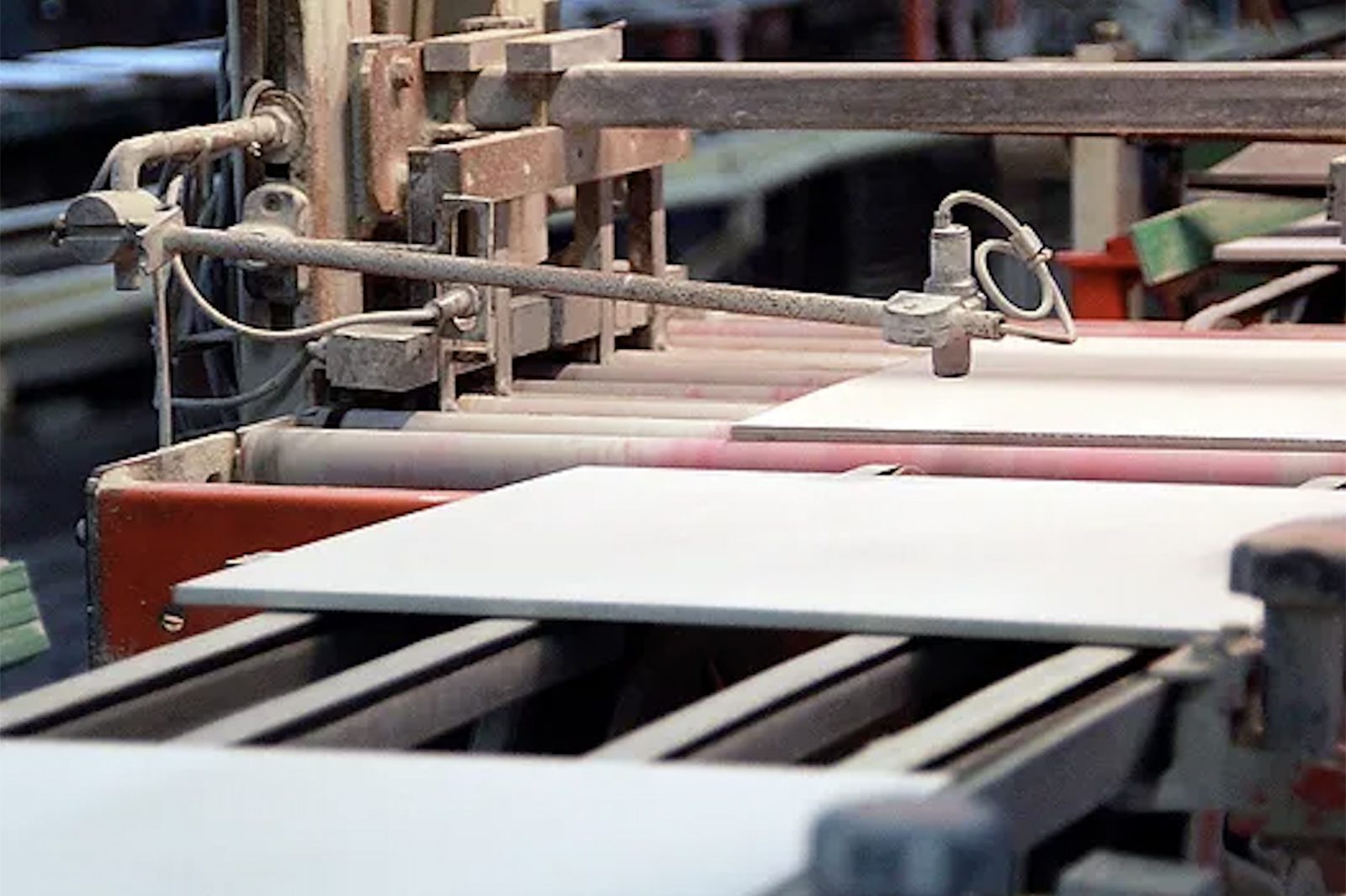

The video goes through the different stages of production, starting with the congeneration, a state-of-the-art process that produces the atomised powder with which the tiles are later shaped and pressed. Once they have acquired their final shape, they are placed in a dryer to reduce their humidity and increase their mechanical resistance.

Then, with the help of digital printing, the tiles are coated with one or more layers of glaze, a treatment that gives the surface a series of technical and aesthetic properties such as shine, colour and impermeability.

It is at this point in the process that the tiles are placed in a continuous kiln where they are subjected to a thermal cycle at high temperatures, obtaining different products depending on the composition, the temperature curve and the duration of the cycle. This causes a fundamental modification in their properties, giving rise to a hard material with excellent performance.

Finally, the process concludes with additional treatments, such as pre-cutting, surface polishing, grinding and bevelling. The result is a product that is perfectly controlled in terms of dimensional regularity, surface appearance and mechanical and chemical characteristics.