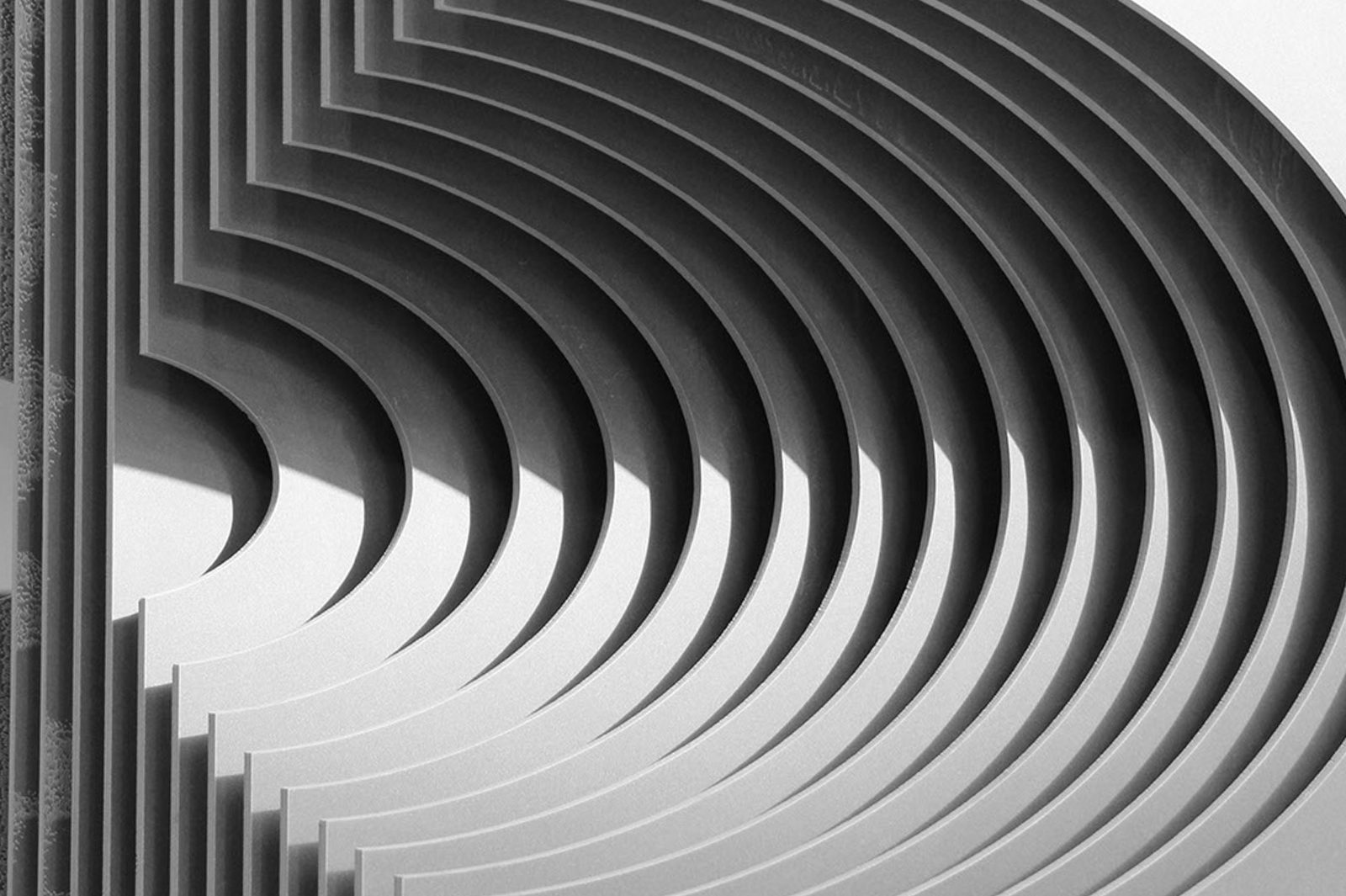

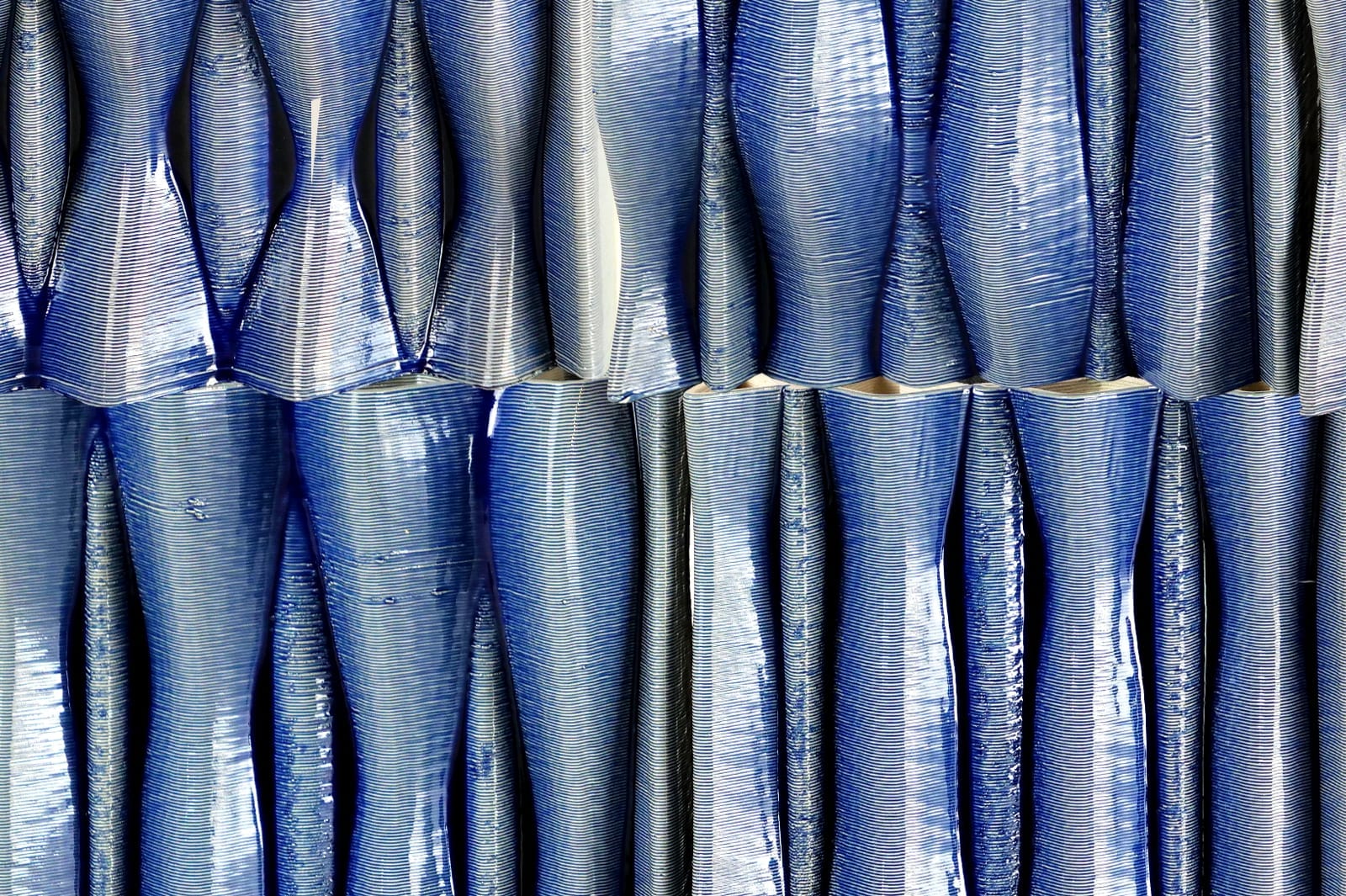

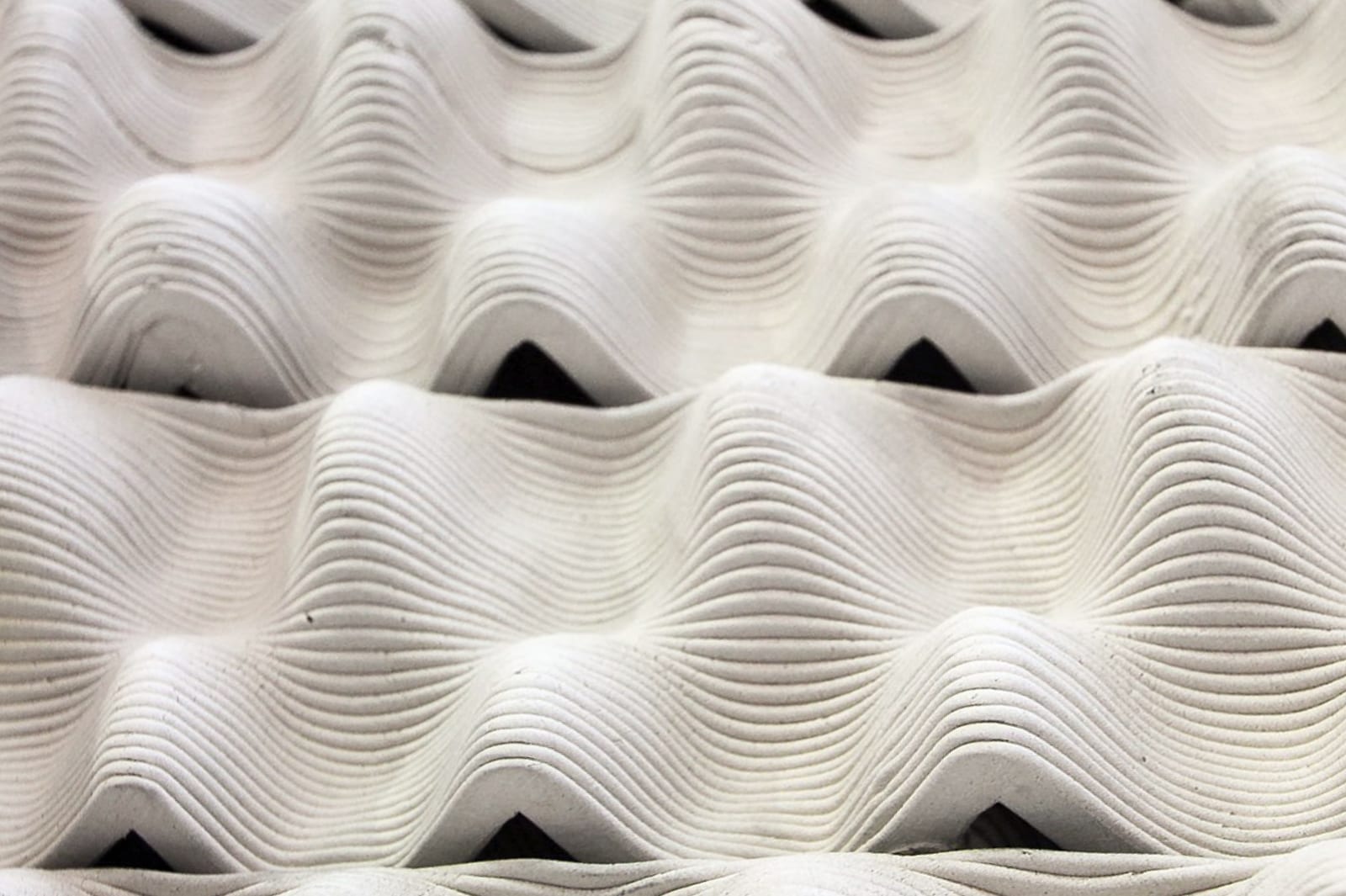

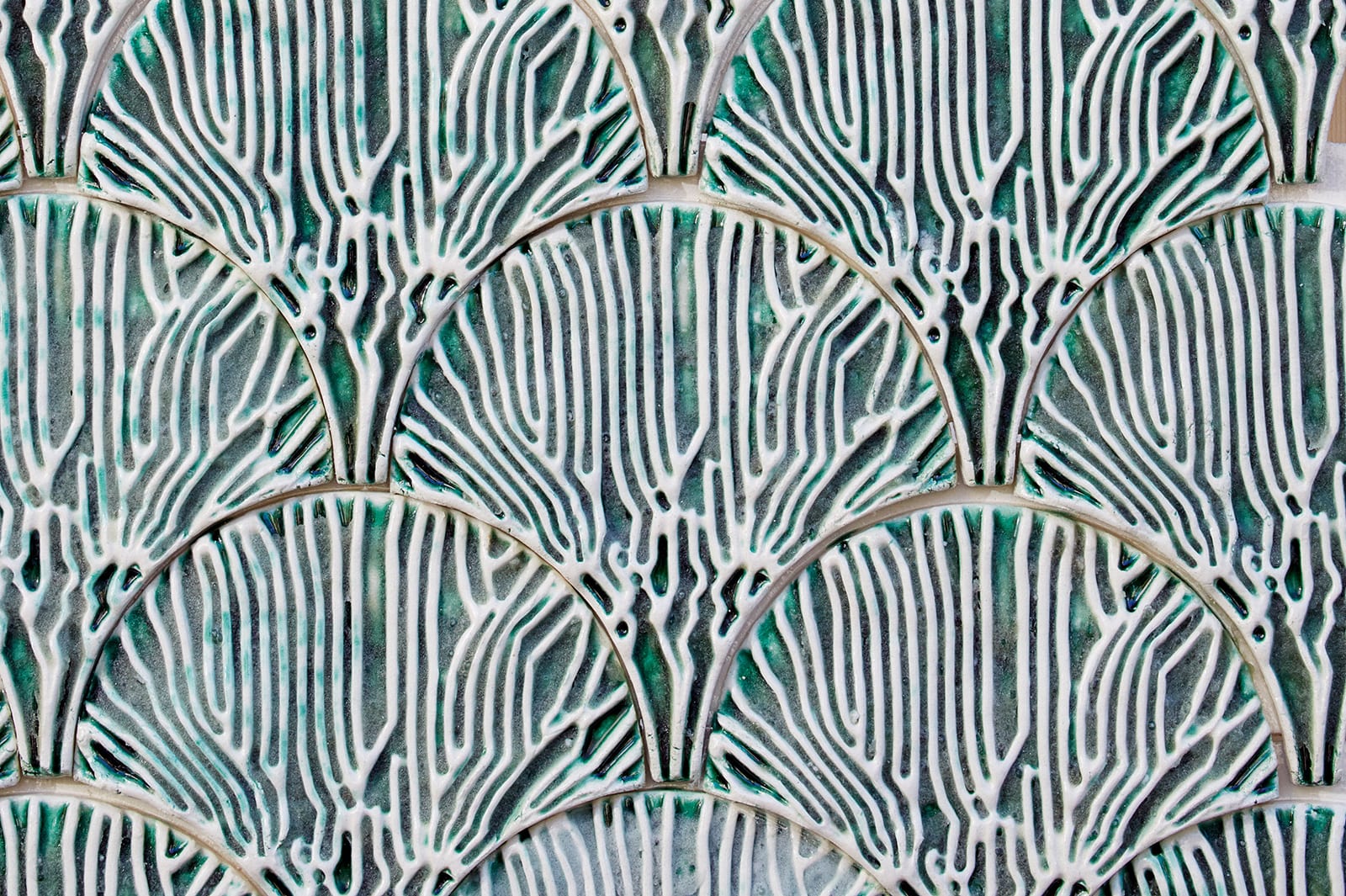

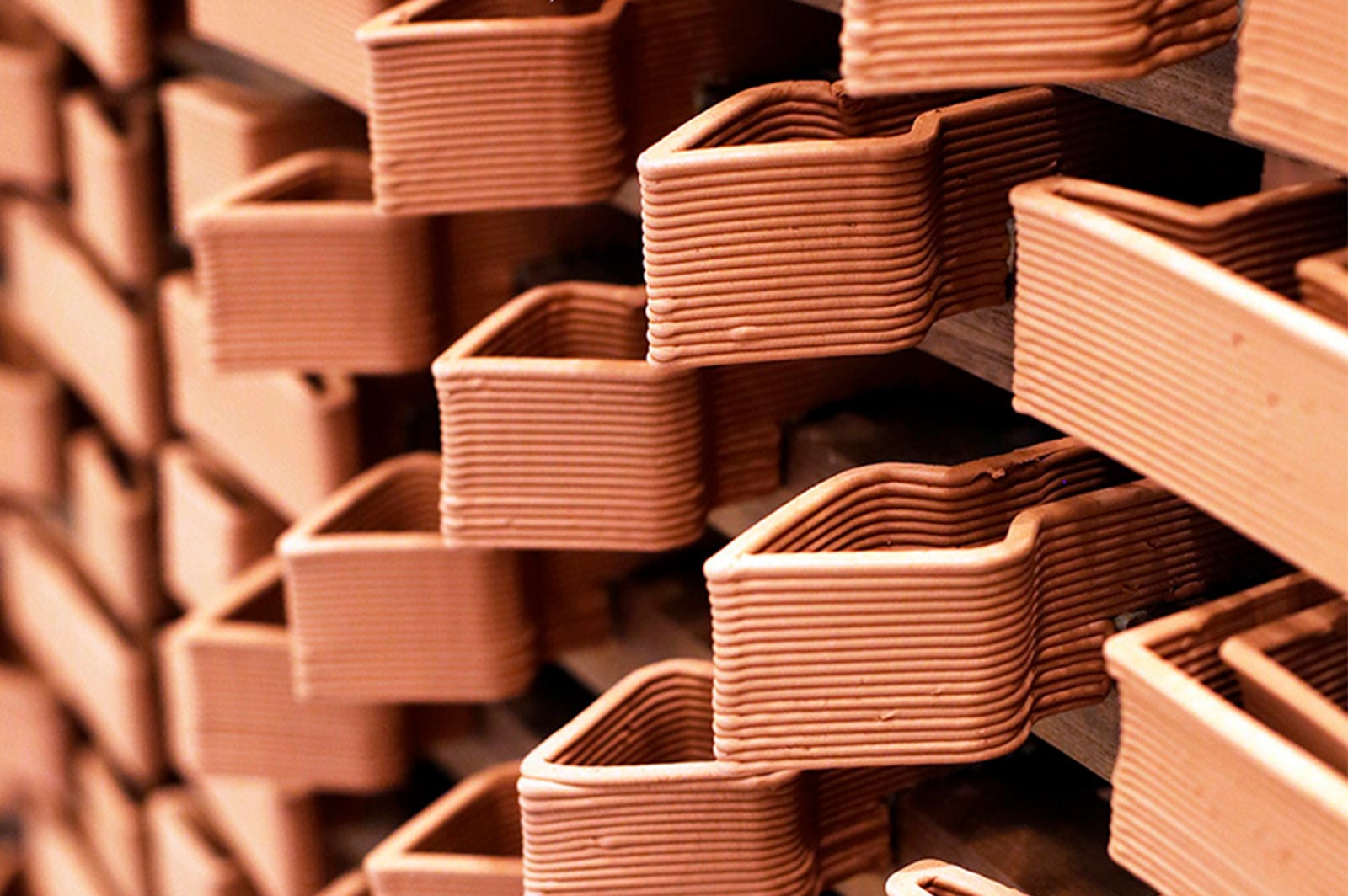

The facade of the M+ Museum designed by Herzog & de Meuron in Hong Kong is much more than just an architectural skin, it is a work of craftsmanship and design. At first glance, the building may appear black or grey, but in reality, its surface reveals a deep, dark green that changes with the light. M+ is wrapped in corrugated ceramic tiles that protect the building and its collections while also creating a dynamic visual identity.

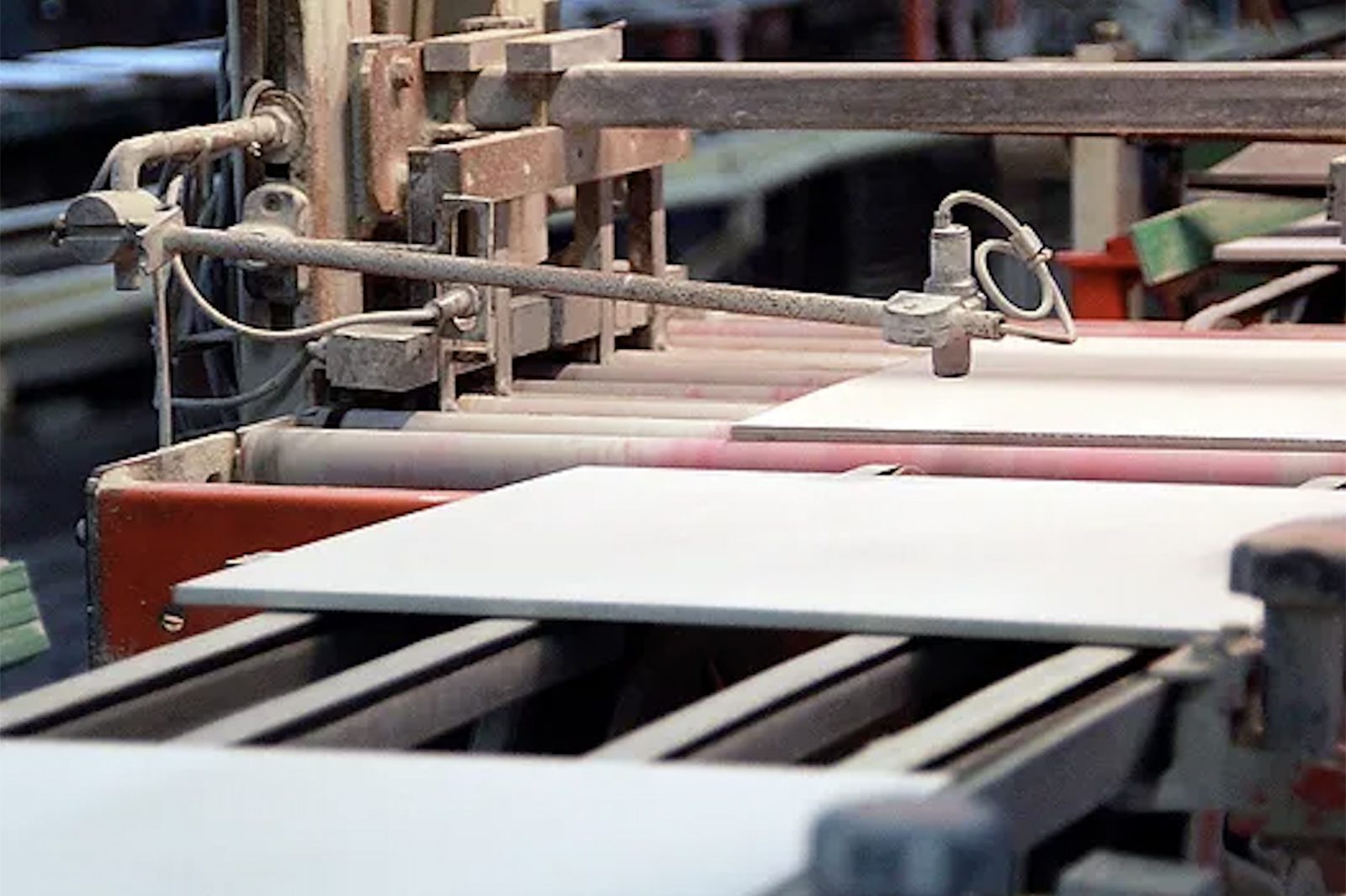

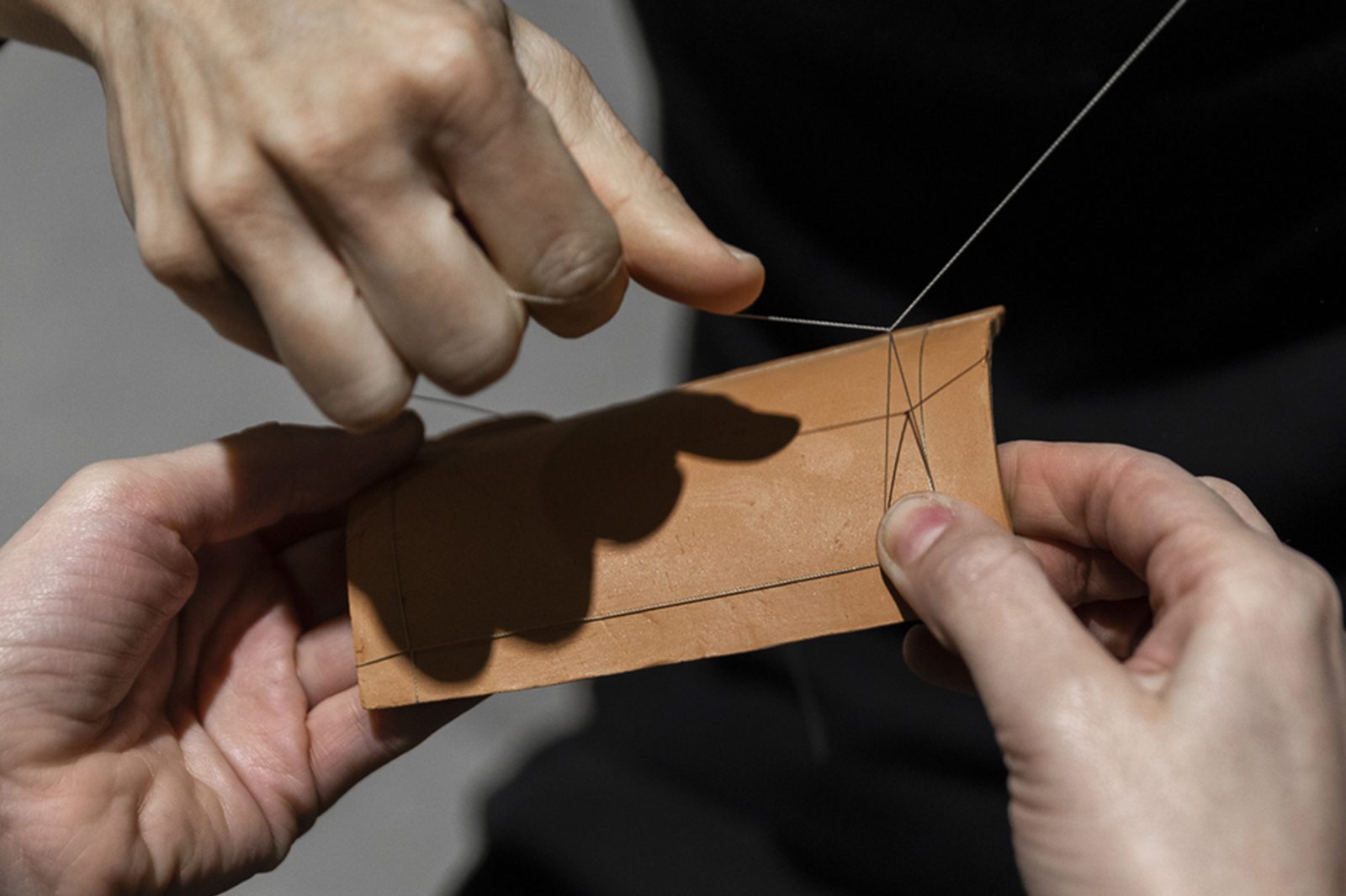

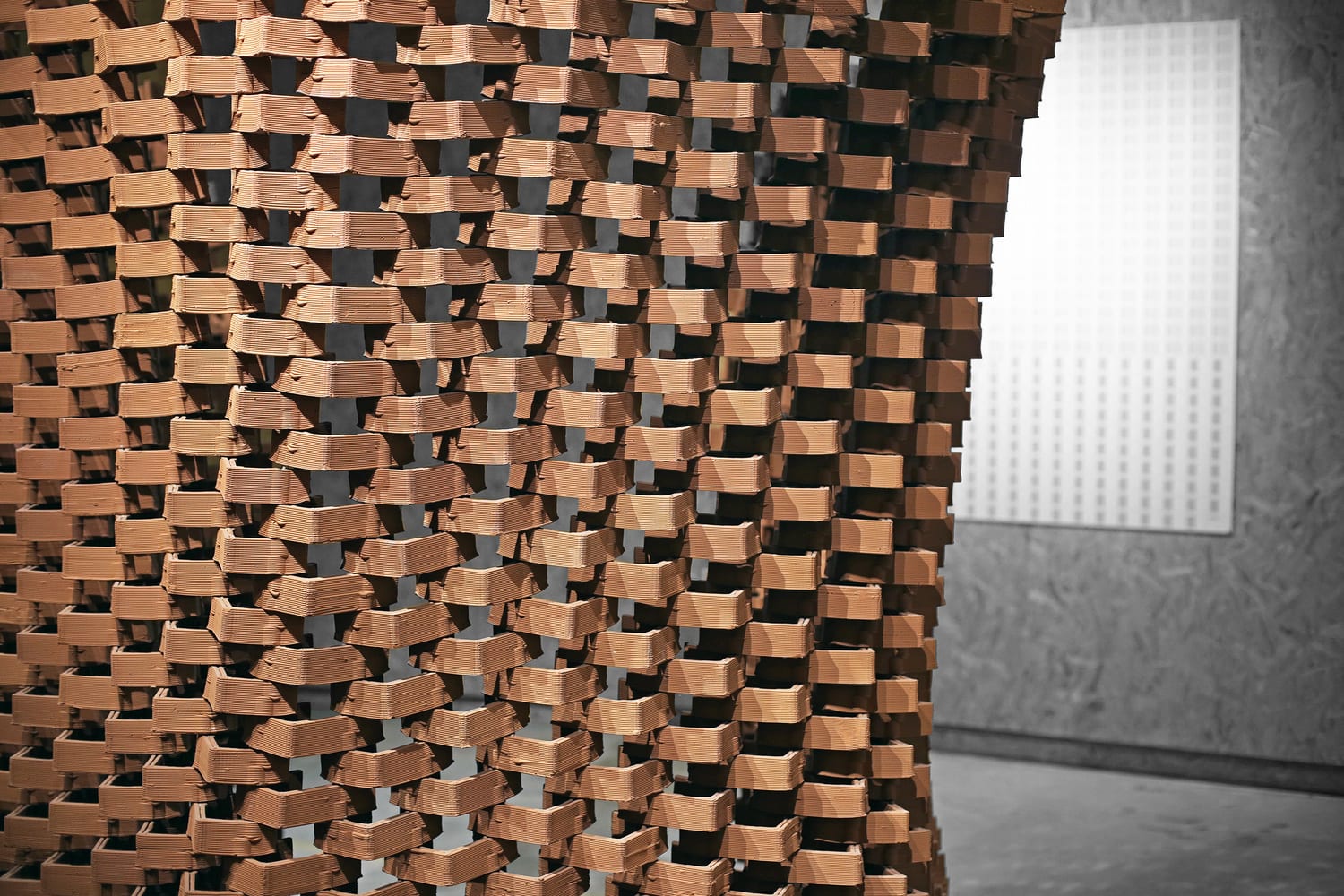

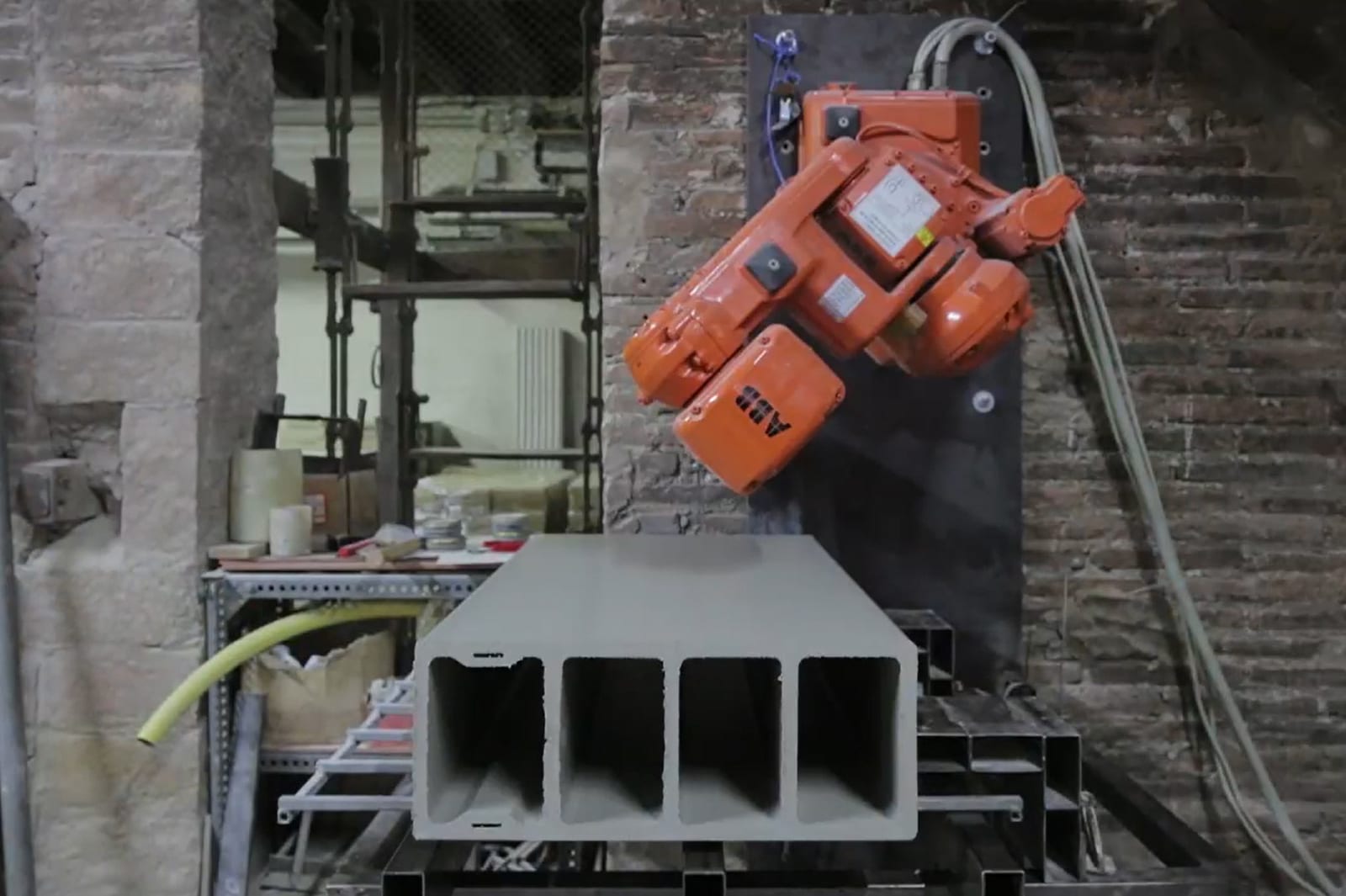

Each tile tells a story of material and process. Natural clays were carefully cleaned, moulded, glazed, and fired in a small factory in Florence, Italy. The glaze, rich in minerals, gives the tiles subtle variations that respond beautifully to their environment: shimmering under the sun, or darkening gracefully in the shade, like the shifting waters of Victoria Harbour.

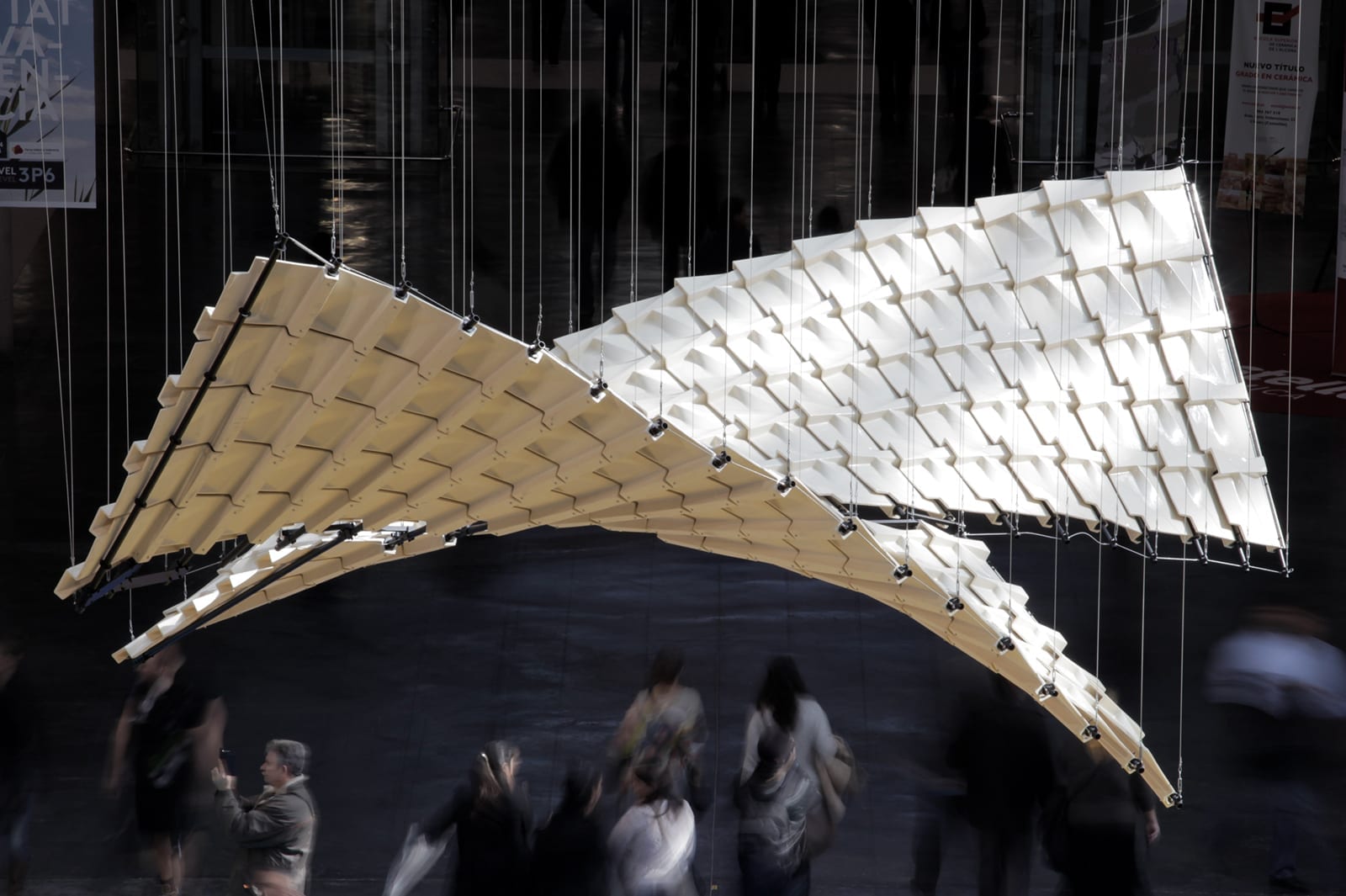

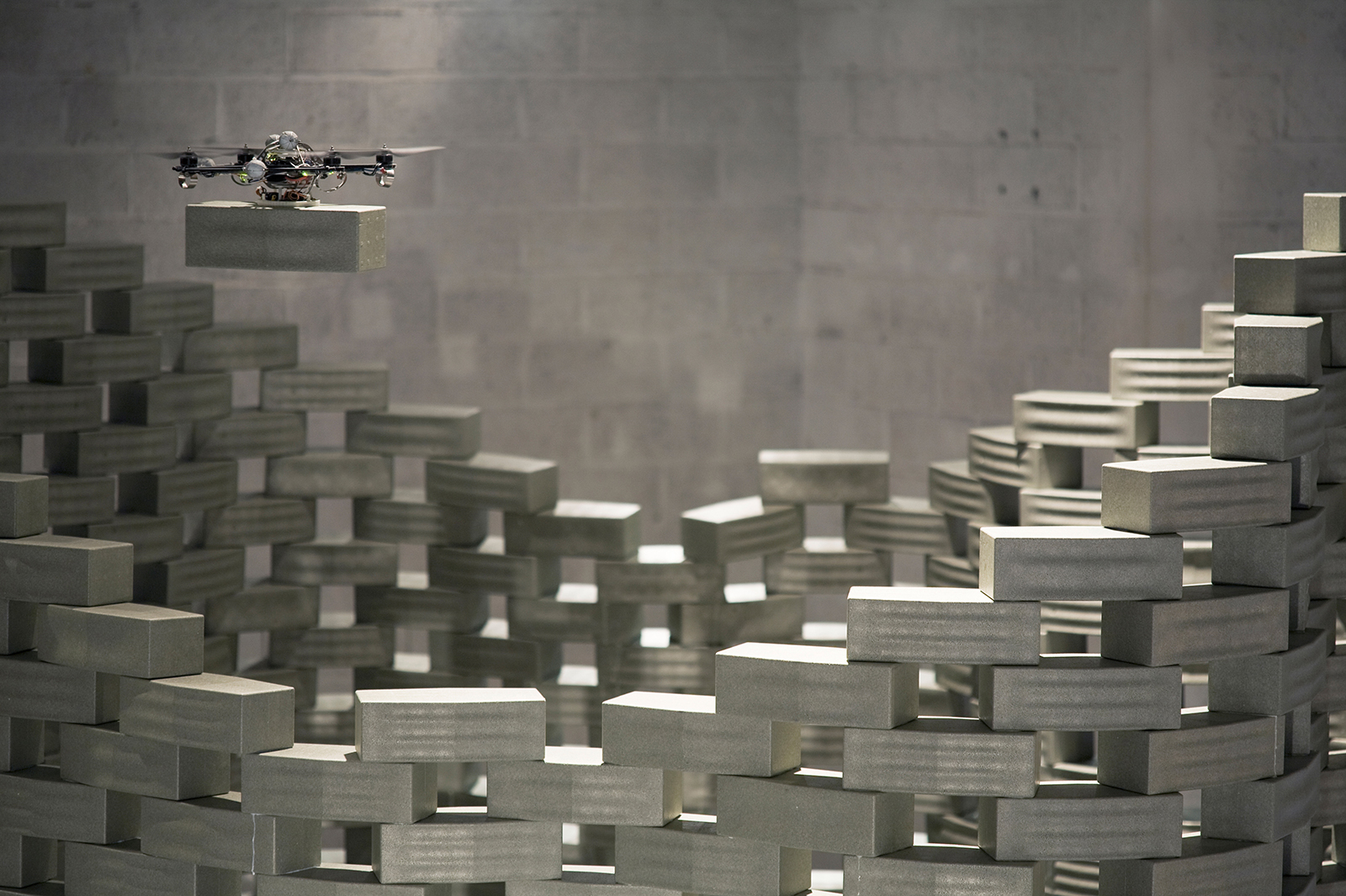

This video offers a rare glimpse into the journey of these tiles—from their handmade origins in Italy to their installation on the museum’s facade in Hong Kong. It is a celebration of the meeting between tradition and innovation, and of the artisanship that gives M+ its unique character.