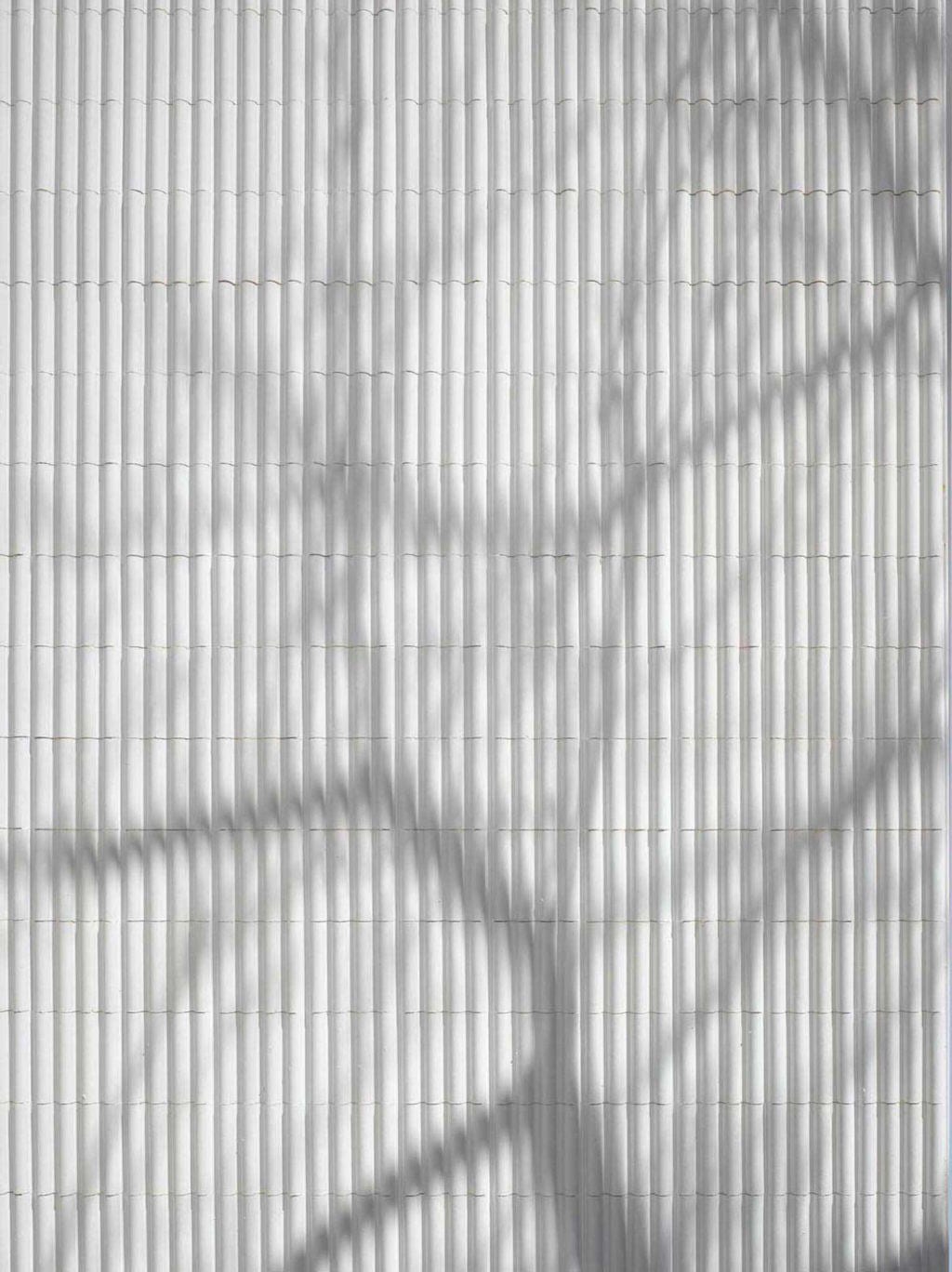

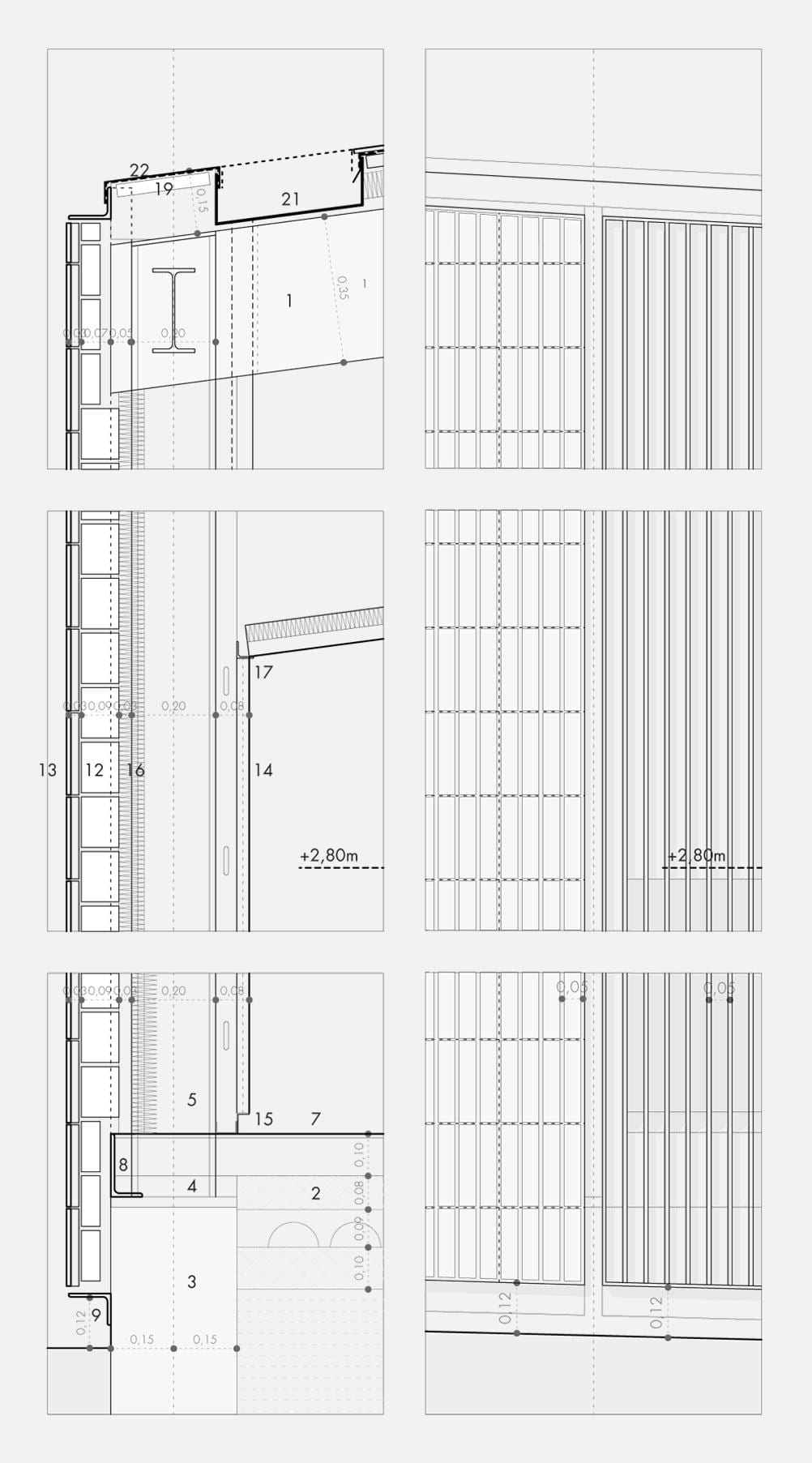

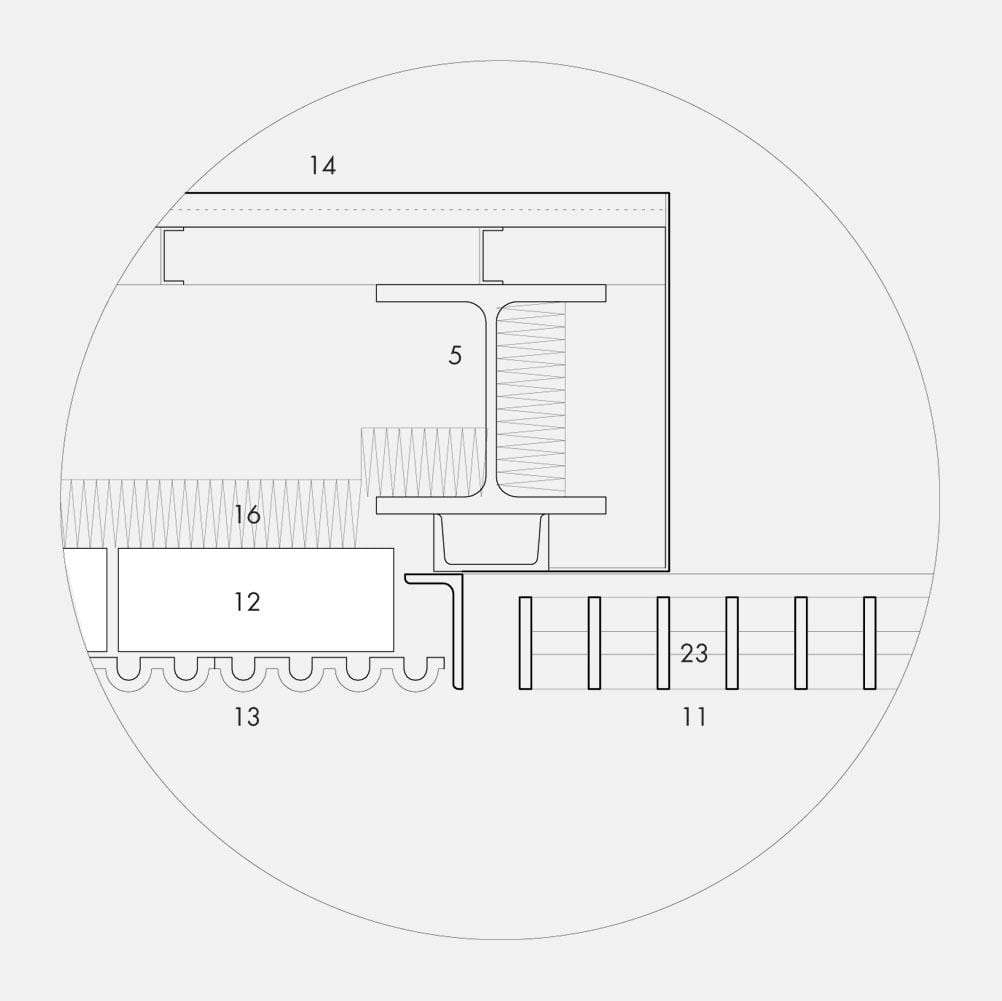

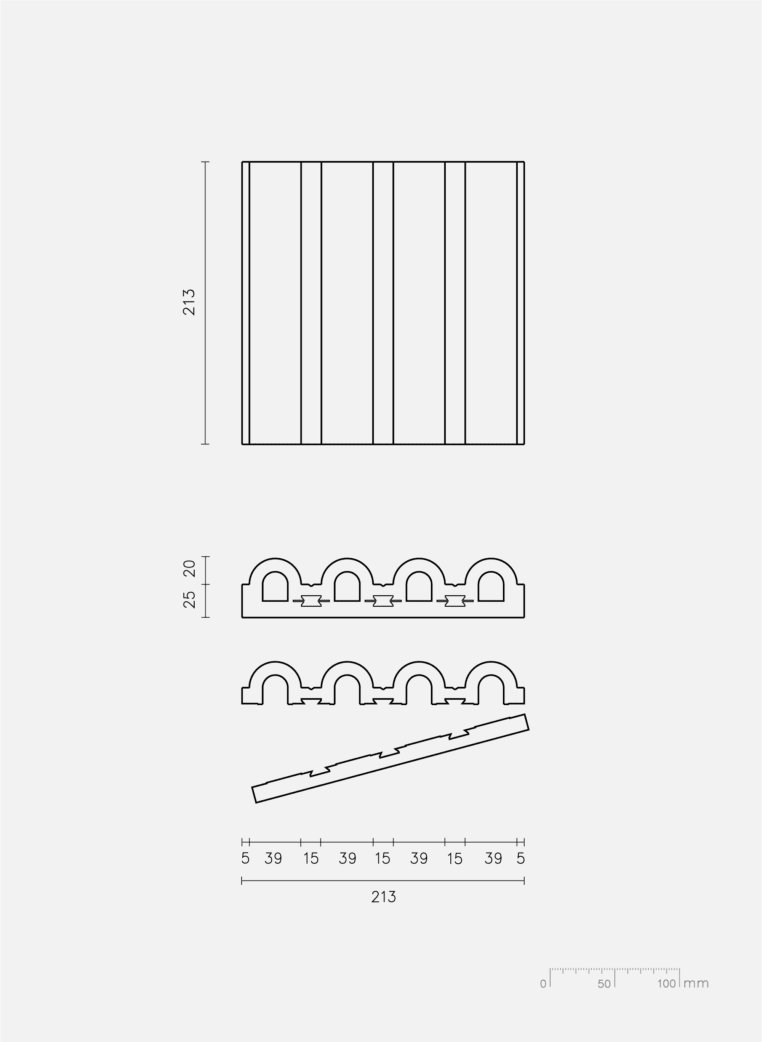

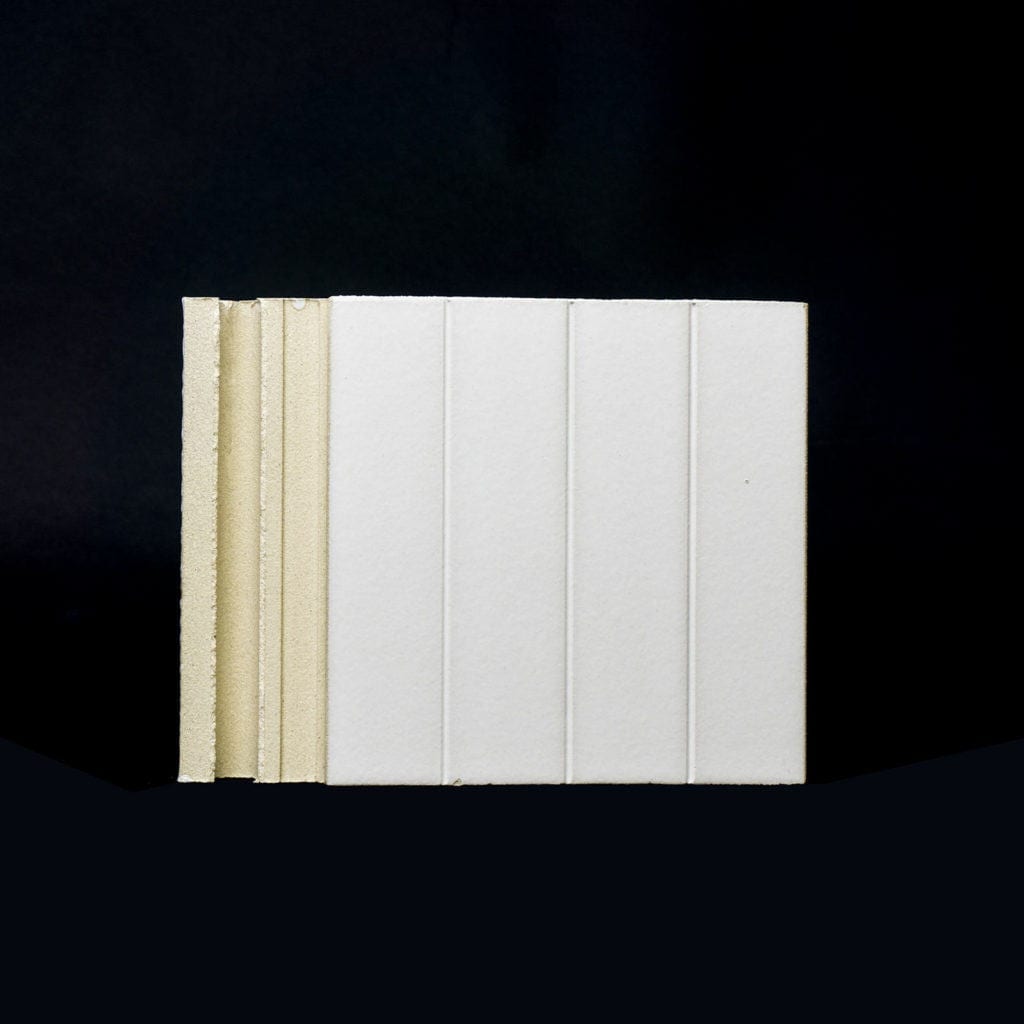

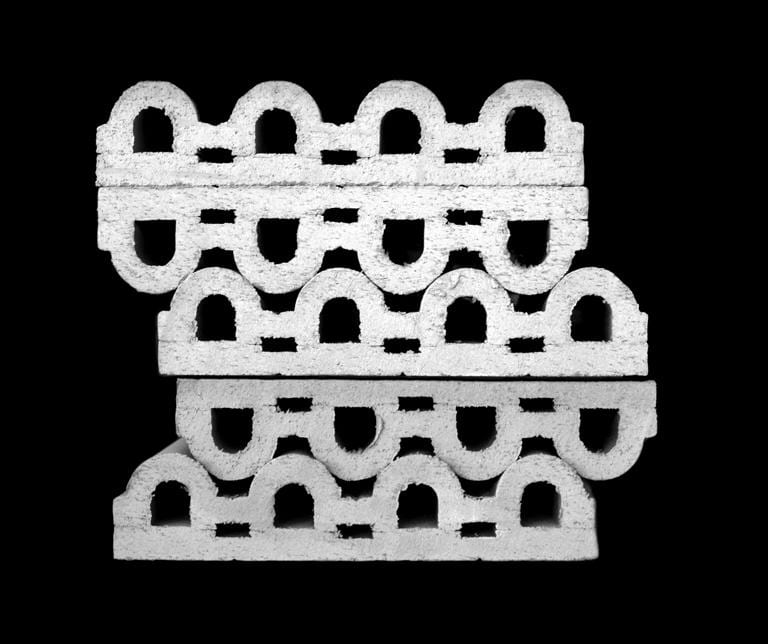

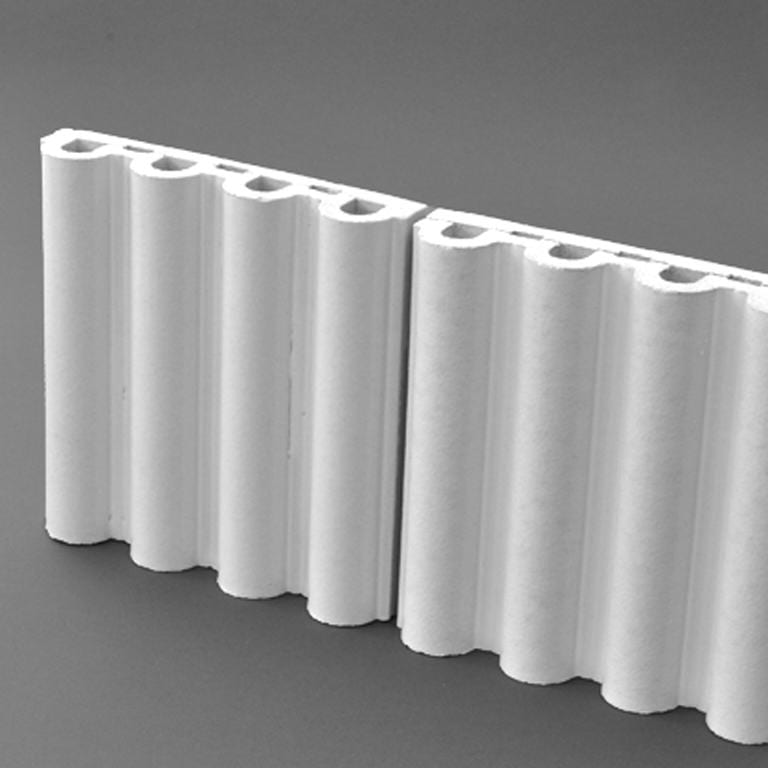

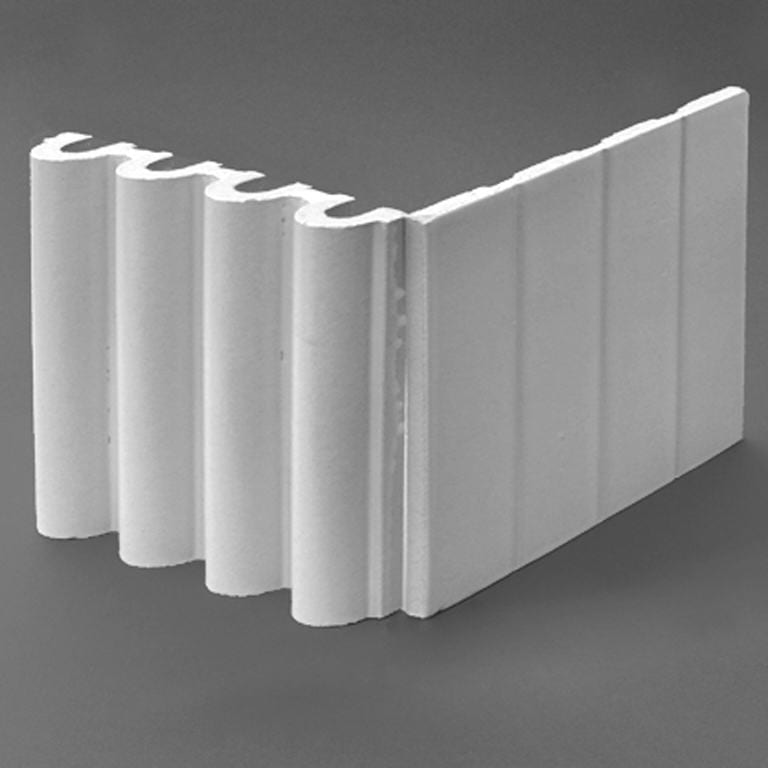

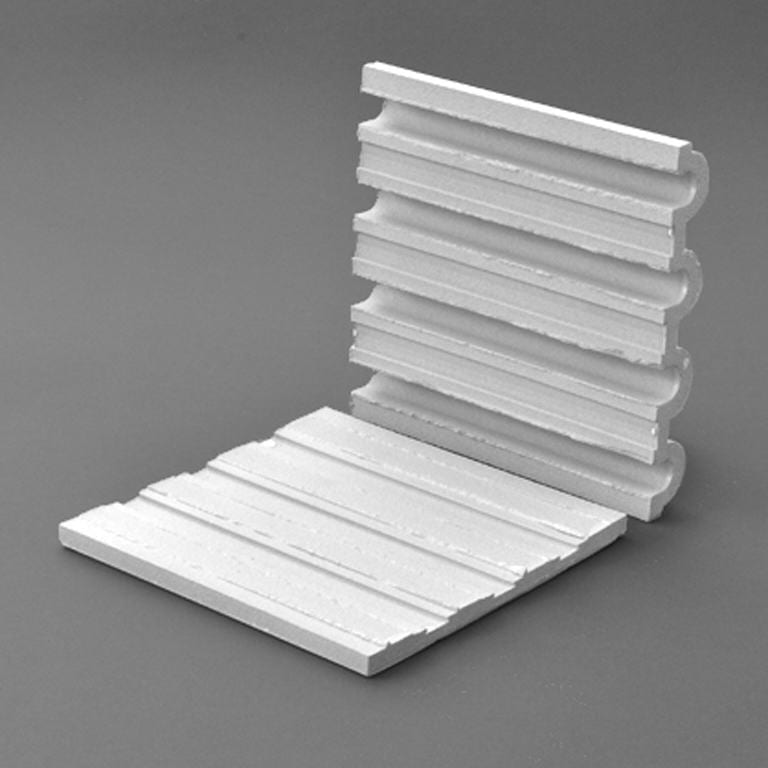

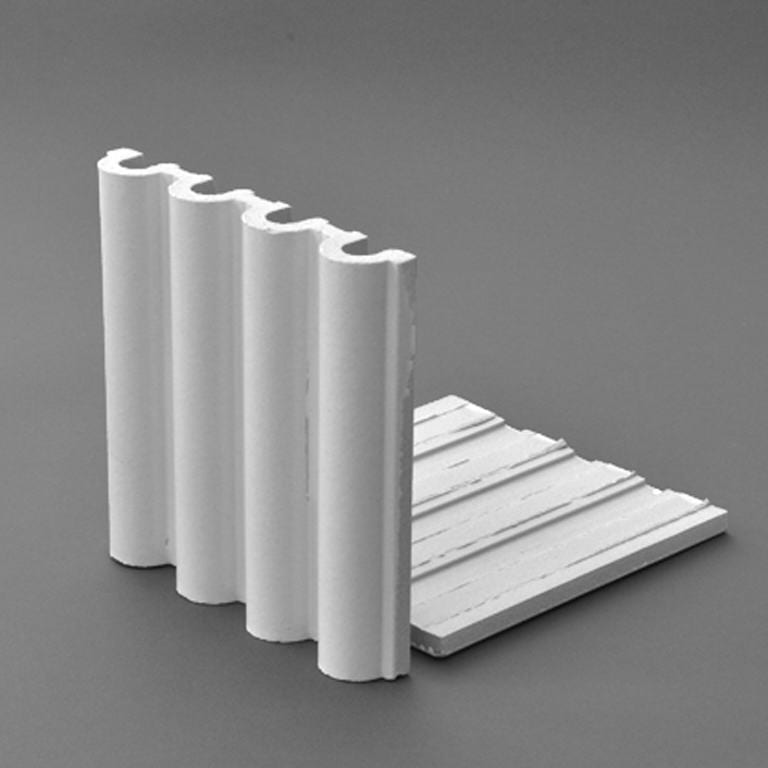

The ceramic pieces manufactured by Ceràmica Cumella are serial components 20 x 20 x 5 cm in size, with 4 waves formed on their surface, each with a 4 cm diameter on one side and four flat boards on the other side. The flat side is necessary for the manufacture and firing of the three dimensional piece, and at design phase, consideration was given to the requirement to not discard this material after firing, but rather use it after the complete enamelling of the piece, in the construction of the roof of the building. In this way, the possibilities of the ceramic piece are fully taken advantage of, using the leftover ceramic and doubling the usage of square meters built.

The pieces are made of stoneware, are obtained through the extrusion process, and are screen enamelled in a disk cabinet with a matt white enamel that is made in house and fired at high temperature (1250 °C) to ensure compliance with the regulations in force with respect to ice, and to attack by acids and alkalis, whilst also having a high resistance to impact. The pieces, now enamelled, are cut through the middle, and both sides separated. Both A and B sides, now separate, have, on their non enamelled interior, a dovetail to ease attachment to the walls and roof.