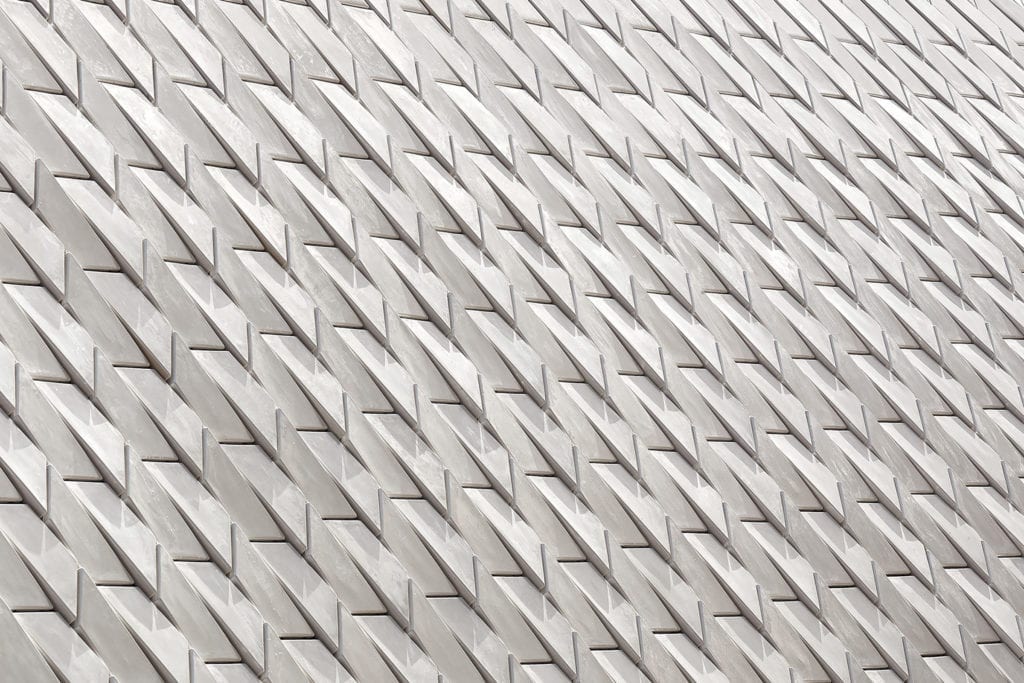

The facade of the MAAT museum continued AL_A’s ongoing research into new uses and reinterpretations of ceramics. The textured façade is composed of almost 15,000 three-dimensional crackle-glazed tiles manufactured by Ceràmica Cumella, which capture the changing light and give mutable readings of the exceptional southern light that vary with the time of day and the seasons.

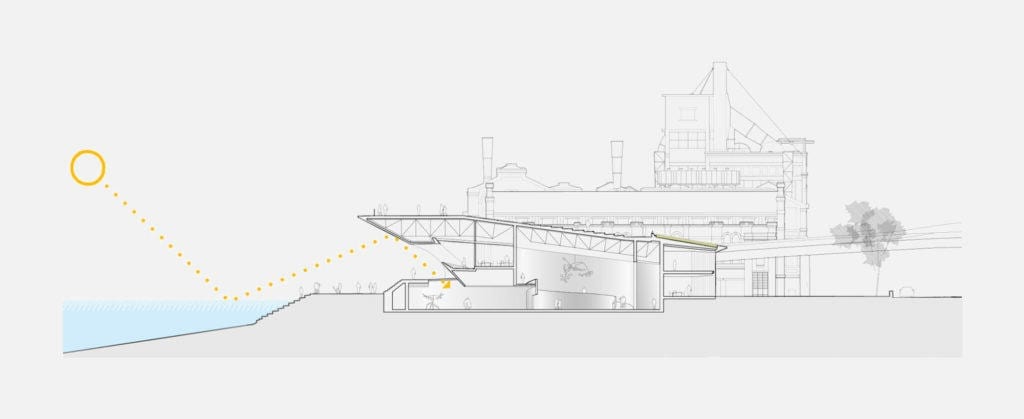

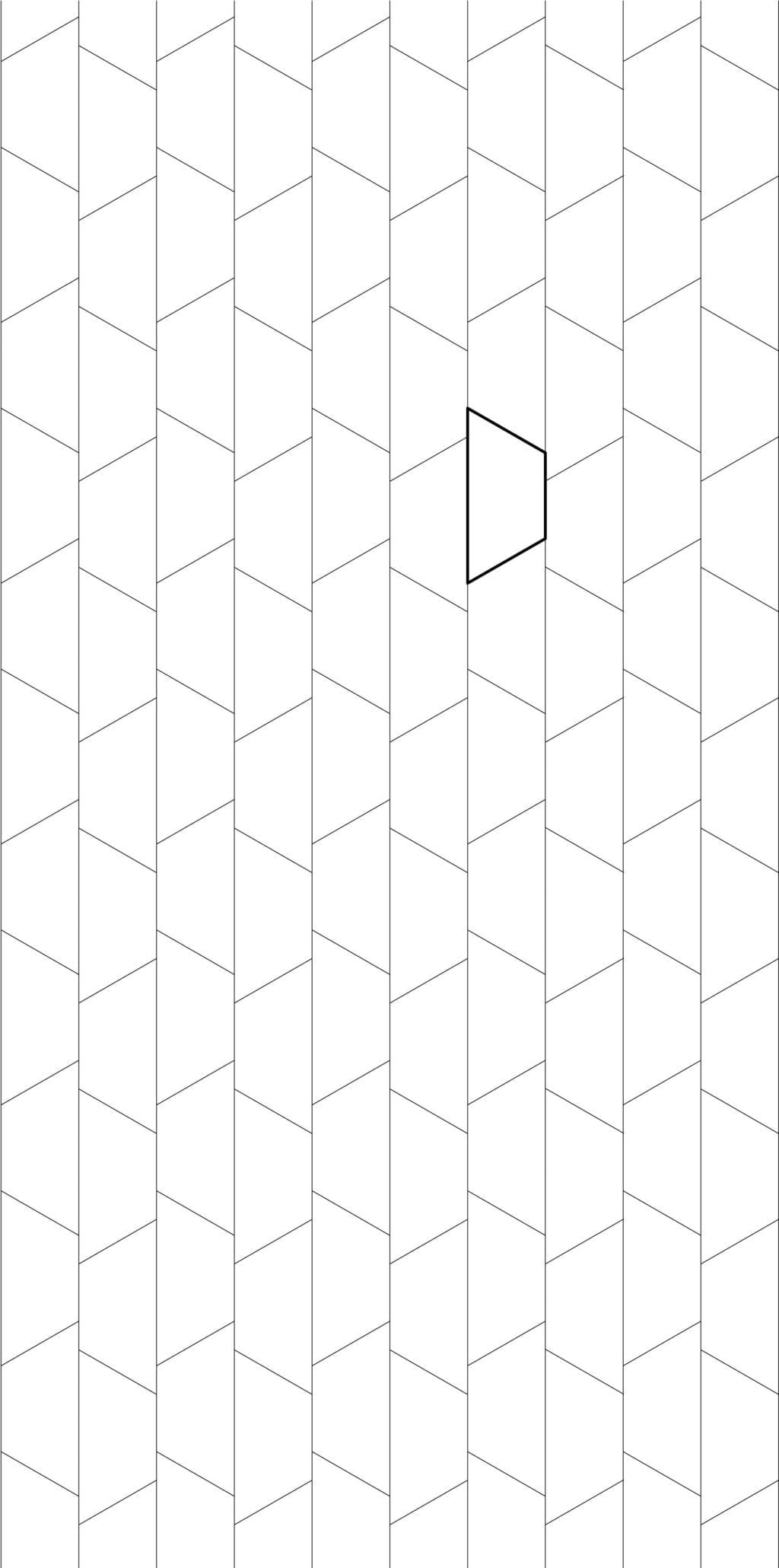

The development of the tiling and modulation evolved hand in hand with the surface of the façade. The challenge was to find a simple, affordable solution that would adapt to the surface and still recreate all the reflections and play with light and shadow that we envisioned. The solution had to address the budget and it was evident that it had to be based on a modular system made out of few tile types as the cost of the moulds or other CNC manufacturing processes would be restrictive. We looked at several grid alternatives, the solution arose with a split hexagonal grid as it could adapt easily to the ruled surfaces and to the areas of transition composed of a gentle double curvature. By creating a 3D tiling system, it allowed us to articulate the façade in a way that we could reflect light in different directions and easily accommodate to the surface geometry. Light is reflected not just from the sky but also the water. The change of the sun allows different kinds of shadows and as the day progresses, the appearance of the building changes. The overhanging of the façade also creates lighting effects both inside and out, capturing and magnifying the unique light qualities of this south facing site and the continually changing conditions.

By rotating the adjacent modules through 180 degrees against each other, we achieved a sequence of tiles which recreate the undulating effect of the surface of the water. This articulation creates shadows that will continuously change throughout the day, acting as a sundial, with dramatic effects and long shadows cast by the sunrise and sunset.

The ceramic façade system developed for MAAT was the first of its kind to obtain a full certification by LNEC (Laboratorio Nacional de Engenharia Civil). Throughout the certification process the ceramic tiles and their fixing systems underwent a series of exhaustive testing that have set new standards in Portugal.